Unleashing Network Transformation

From 5G to Converged AI+5G for O-RAN Networks

Complete O-RAN Capabilities

Design

- Capture customer requirements

- System co-design with customers

Development

- PHY software development

- L2/L3 software development and optimization

- Platforms: SoC, DSC, CPU, FPGA, GPU

Integration

- Collaborative system integration & project management

- Fronthaul Integration between DU and RU

- PHY/L2/L3 software integration

Algorithm

- Tracking 3GPP standards

- Algorithm design and simulation

Testing

- Lab and field testing

- Test cases

- Debugging tools

- ATE (Automated Test Environment)

Maintenance

- Rapid resolution of field issues

- Continuous enhancements

- Comprehensive training

From 5G to Converged AI + 5G

Market Proven PHY

- Leading 4G+5G L1/L2/L3 O-RAN software provider

- 3GPP compliant PHY software with a rich feature set

Reliable, flexible and scalable

Strong System Integration

- O–DU/O–RU fronthaul interfaces certified by O-RAN with Keysight and Viavi test equipment

- Integration with more than 6 different L2/L3 stacks

- Integration with more than 6 different 5GC core networks

Hyperconverged AI+XG

- Most advanced AI+XG system powered by NVIDIA GPU

- Computing power at the network edge

- Harnessing 5G’s capabilities for AI in mobile and wireless use cases

Leveraging Our Unique Strengths

Rapid Telco

Integration

Our ready-made solution accelerates entry into the telecommunications space. With RUs and DUs forming the core, our unique L1 software acts as the crucial binding agent. This software can be licensed, offering a quick and efficient path for others to integrate our technology.

Global O-RAN Software Leader

We are a leading provider of Layer 1 (L1) software in the O-RAN sector, offering global solutions that set industry standards.

Empowering Ecosystem Partnerships

Our distinctive L1 software serves as the essential connector within the framework, where RUs and DUs form the core. This high-quality software is available for licensing, providing an expedited and seamless way for other service providers to adopt our technology.

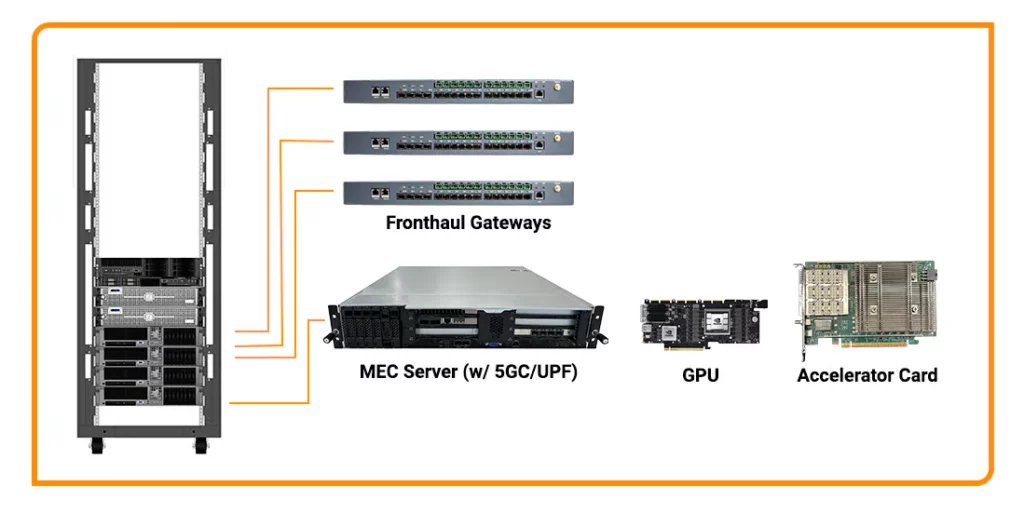

Platform Solutions

SynaXG DU Chip Platforms

PHY Hardware Accelerator Chips

Server CPUs

Use Cases

Factory Deployment

SynaXG enables smart manufacturing, warehousing and logistics through converged AI and XG technologies. Our solution connects people, machines, and processes to boost efficiency across inventory, picking, processing, assembly, and handling operations.

With 5G’s high speed, low latency, and precise positioning, SynaXG enables innovative AI+XG solutions for factories and warehouses, accelerating digitization and automation, enhancing quality control and regulatory compliance, coordinating equipment, robots, and workers seamlessly, reducing costs through AI optimization and automation, improving productivity and asset utilization, providing real-time visibility into operations, and enabling rapid scalability and flexibility.

SynaXG delivers the power of edge AI and 5G in one solution to build future-ready intelligent factories and warehouses. Our unified platform connects your physical and digital ecosystems to increase efficiency, lower costs, and drive growth.

Reduced Labor Costs

AI-powered defect detection is up to 20 times faster than manual methods (0.5 seconds vs. 10 seconds per item).

Lower deployment costs

Wireless 5G connectivity reduces expenses by 30% compared to wired setups by eliminating costly wiring in factories.

Hardware savings

Converged 5G and AI solutions share the same computing resources.

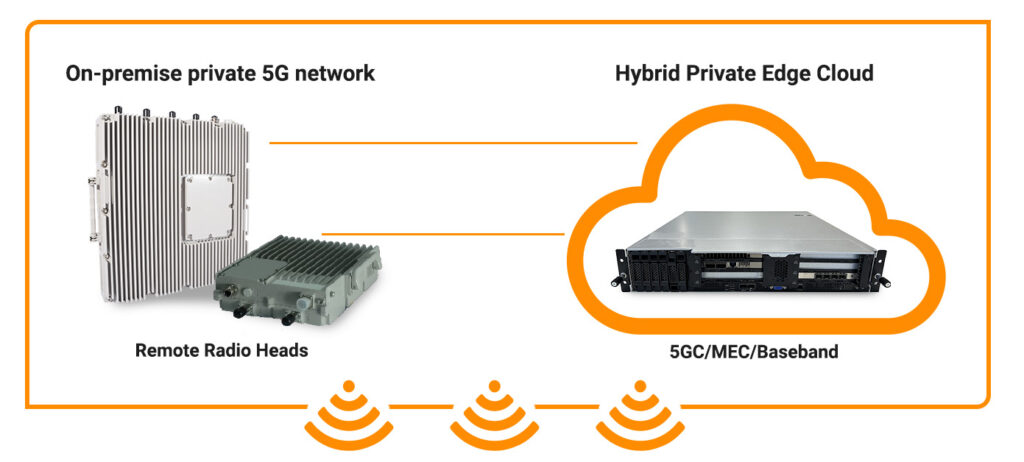

On-premises Private 5G Brings Full Automation to Ports

Our on-premises private 5G solution enables seamless wireless coverage across berths, cranes, and stockyards and provides precise location tracking of automated guided vehicles, cranes, and cargo, enabling efficient operations and inventory management across extensive terminal areas. The benefits of autonomous operations enabled by private AI+5G networks are profound:

Reduce operator headcount by 85% and improve efficiency by 30%

A single remote operator can control 3-6 gantry cranes simultaneously, while also improving working conditions and reducing demands on crane drivers, enhancing safety.

Achieve 99.999% remote control reliability

Minimal downtime – as low as 5 minutes annually -- increases port crane efficiency and maximizes economic benefits.

Leverage dedicated private networks for security

Ensure data and information security without external leaks, improving system stability.